Microtunneling e direct pipe

1468 – Piombino

Works:

FRSU Piombino line and dock construction. Execution of crossing by Direct Pipe

Customer:

Snam Rete Gas S.P.A.

Buyer:

Max Streicher S.p.A

Period of Execution:

November 2022 - April 2023

Works Amount:

€ 5.900.000,00

Description

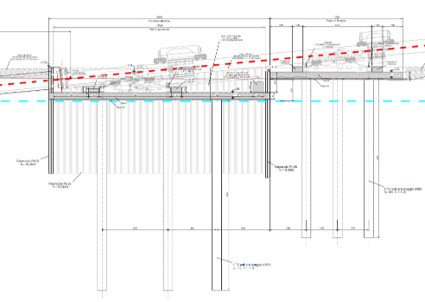

The works involving the construction of the FRSU Terminal at Piombino and its connecting works were divided into 3 distinct sections:

- quayside section

- section in Direct Pipe

- underground section with double pipe.

The Contractor entrusted I.CO.P. with the construction of the second section, interposed between the quay and the coast, the development of which, starting from the thrust shaft on land, crossed the marine gulf until reaching the arrival shaft on artificial quay.

The thrust post was constructed by means of an excavation, about 2m deep from p.c., with a rectangular plan about 20m long in the direction of the thrust axis and about 7.5m in the direction orthogonal to the axis. The post walls are vertical and are supported by vibro-infixed metal sheet piles.

The recovery of the TBM, on the other hand, was done by means of a trench excavation about 1.2m deep since the connection between the DP and the line pipe at the dock was at ground level.

Characteristics of the intervention

- Production recorded the following values:

- Drilling days: 20

- Maximum daily production: 130 m

- Average production on actual drilling days: 65.40 m

- The lithological units traversed were not in line with preliminary surveys, showing instead a marked geological alternation (fine to medium coarse sands)

- Limited polymer consumption in the drilling fluid and absence of coagulants

- The reduced natural overburden at the start implied, in order to avoid possible subsidence phenomena in the soil overlying the first meters of drilling, the realization of a reinforcement and stabilization of the initial section until a suitable depth was reached in the natural soil.

- The stabilization section was confined by 10 m long sheet piles filled with plastic material.

- During the design phase, when analyzing the stratigraphies of the soil affected by the crossing, critical issues were highlighted in the terminal section due to the presence of coarse gravel columns. Therefore, it became necessary to reclaim the area by constructing piles using the CFA technique with plastic material casting (Fillplast).