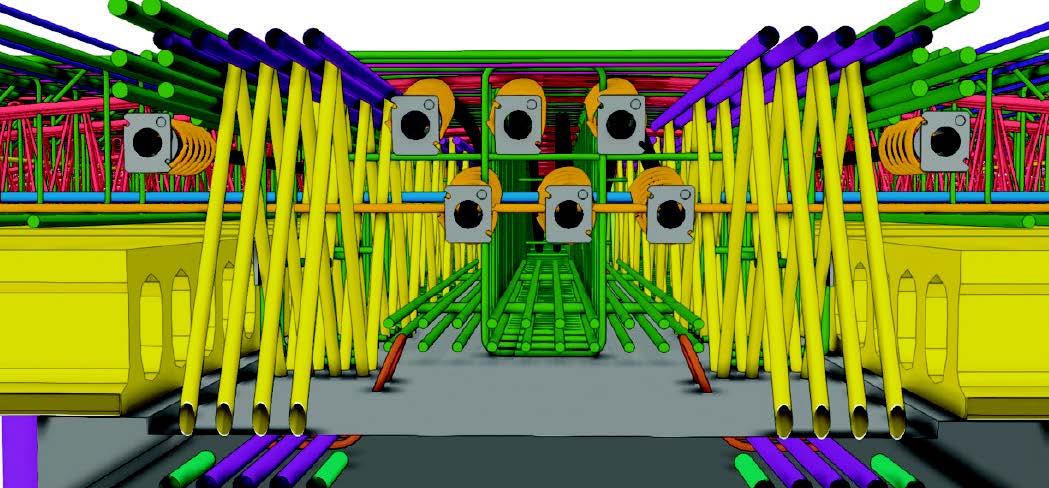

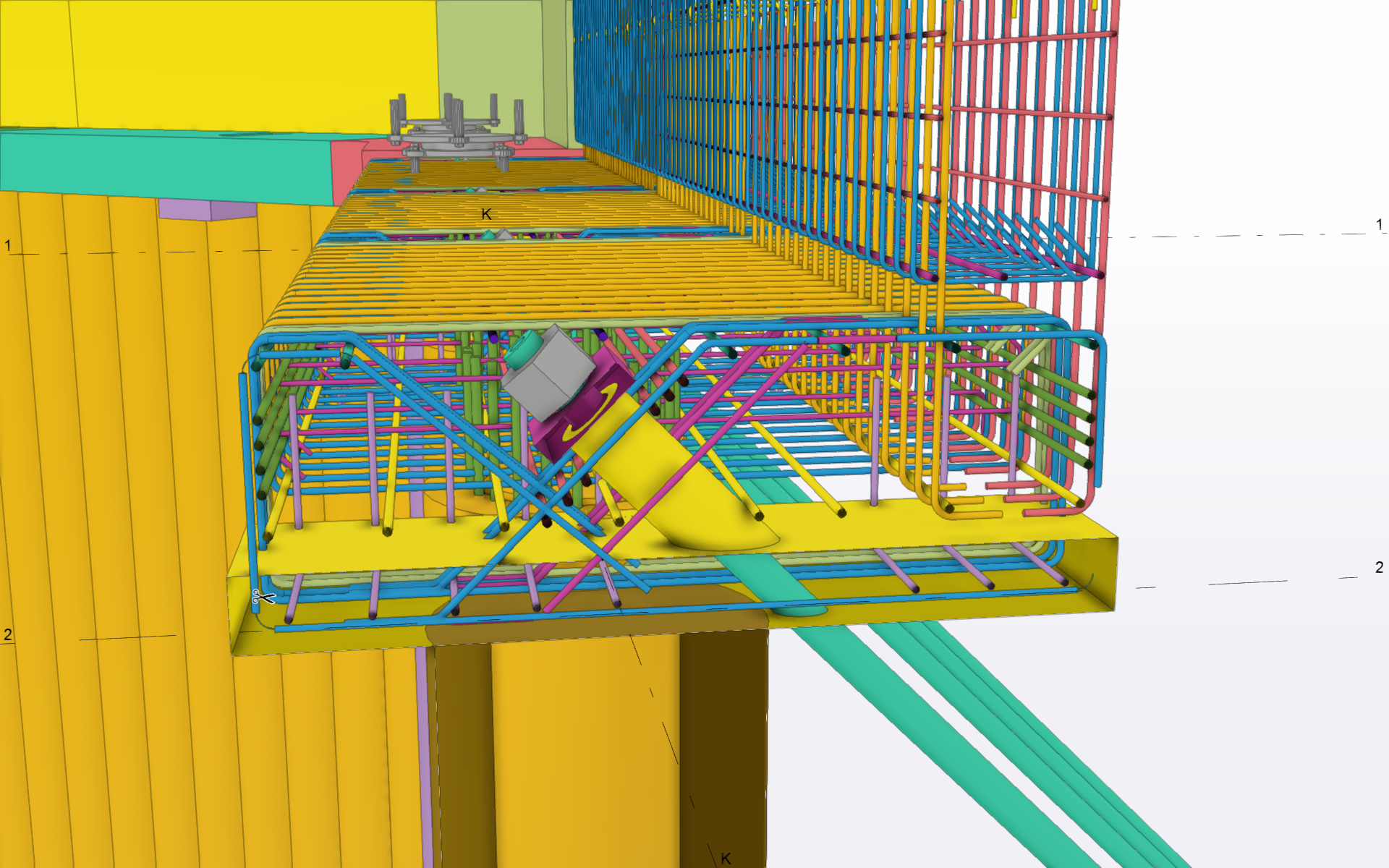

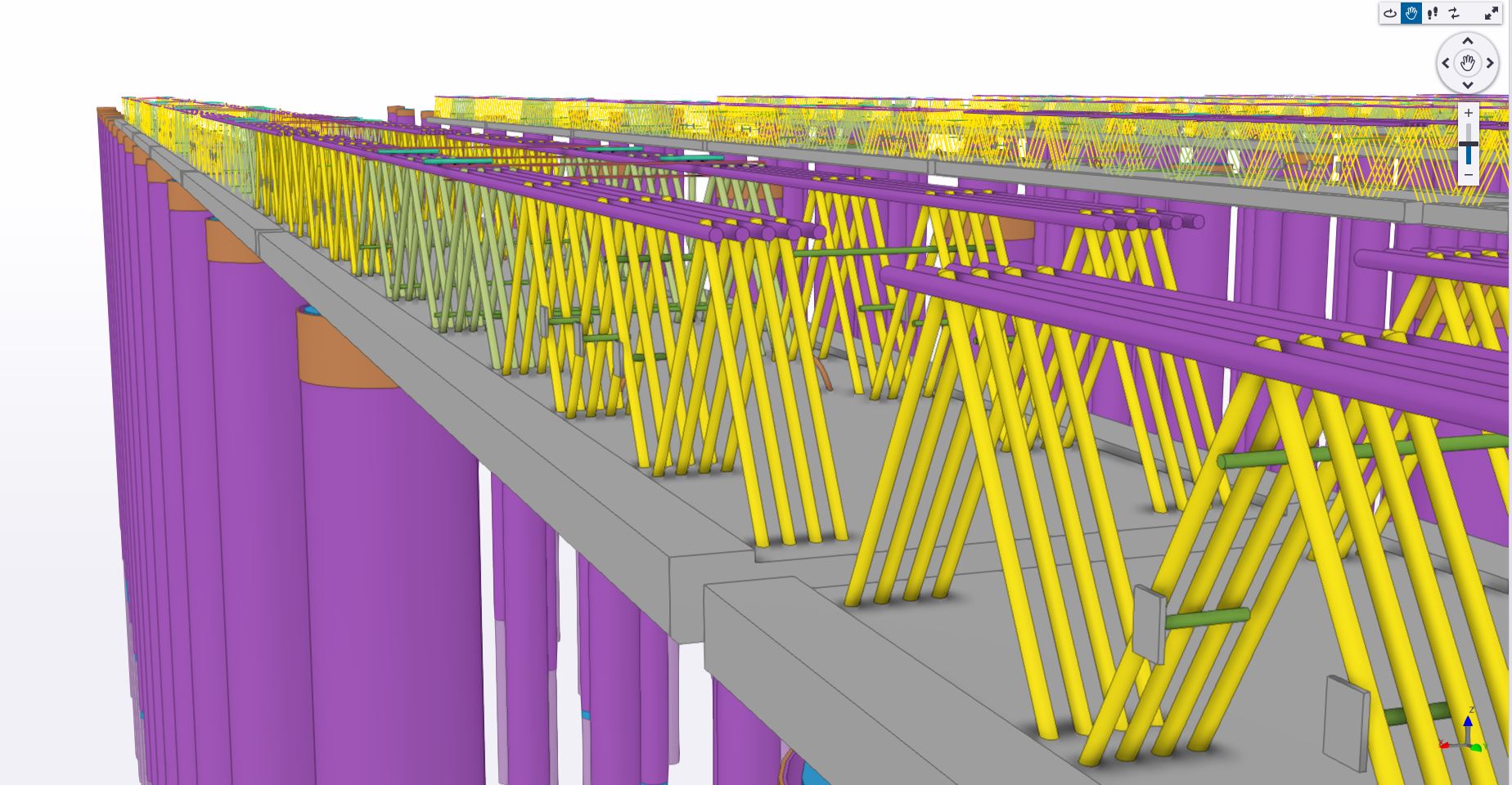

The communication between Engineering and Design Office and construction sites is now even more efficient thanks to the “project collaboration” cloud-based platform, which allows to share in real-time the BIM models and the related parameter data. In fact, the technicians involved in the project can easily display, share, coordinate, and comment the BIM models from everywhere and at any time during all the job stages. This information is therefore available via tablet at the construction site. The latter similarly sends back information, i.e. on co-activities or non-compliances, establishing direct and quick communication between the headquarters and the construction site. The Logistic Platform of Trieste project was the first opportunity to extensively test the new software, which is now implemented in other constructions sites as well.

The main goal of I.CO.P. in these years is achieving and maintaining strong working interaction at all levels of the different corporate functions, by sharing and exchanging information. Many data are produced through the use of modelling software, IT platforms, and site machinery as well.

In fact, several rotary drills and TBMs are equipped with remote data exchange systems, therefore allowing to monitor production even from a technical and maintenance point of view, as well as to effectively manage production data. These data are implemented in a dedicated section of the corporate Intranet. Operators are then able to monitor the construction site in real-time.